Installing a Honda P28 ecu chip

While this covers installing a chip on the USDM version (US Domestic Market) Honda P28 ECM, the procedure is the same for almost all 1992-1995 (OBD-I) Civic and Integra ECMs. The circuits of all of them are based on the same construction design. Those are, but not limited to, the Honda P05, P06, P08, P28, P30, P72, P75, and PR4 (OBD-I version).

This requires electronic components soldering skills, especially when working with these ECM circuits, which are sensitive to overheat when soldering and unsoldering parts on it. Also, you may find it somewhat difficult to desolder parts from these circuit boards because of its multi-layer structure. Multi-layer means that it has connections above, below, and inside the top and bottom circuit board layers.

First, uninstall the ECM from your car. It is be located beneath the carpet in the passenger’s side footrest.

Once you uninstall the ECM from the car, place it on a bench or flat table for working it out. Have handy all the parts in the kit, which are; the Power-ROM chip, the 1K resistor, the two 0.1uf capacitors, the 74HC373 chip, and a wire jumper. The jumper can be any piece of thin wire. A short length cut from the resistor lead will do the job.

Also, have the needed tools handy for this job, which are:

1- A Phillips #2 screwdriver (for removing and replacing the ECM covers)

2- A small flat screwdriver (for prying the chip out of the socket if needed)

3- Small wire cutters or clippers (for cutting excess length of components leads)

4- Long nose pliers (For holding the small parts when installing)

5- 35-watt soldering iron (for soldering/desoldering the parts in the circuit)

6- Desoldering vacuum tool or desoldering braid (for removing parts and cleaning connections)

7- 60/40 rosin core solder

8- Alcohol pads (for cleaning the circuit board from excess soldering flux)

9- Anti-static wrist (for protecting the ECM from static electricity)

10- Soldering flux (liquid or paste, for electronic soldering – DO NOT use plumbing or any acid flux)

Before starting, plug the soldering iron in so it gets ready to use in a few minutes. Also, make sure you put on the anti-static wrist and connect the other end to an earth ground, like a metal conduit of the household electrical circuit. Check #11 of the drawing above for using the electrical household circuit for this. This will protect the ECM and components to be installed. Static electricity may be high enough to damage the ECM if it ever receives a discharge from you.

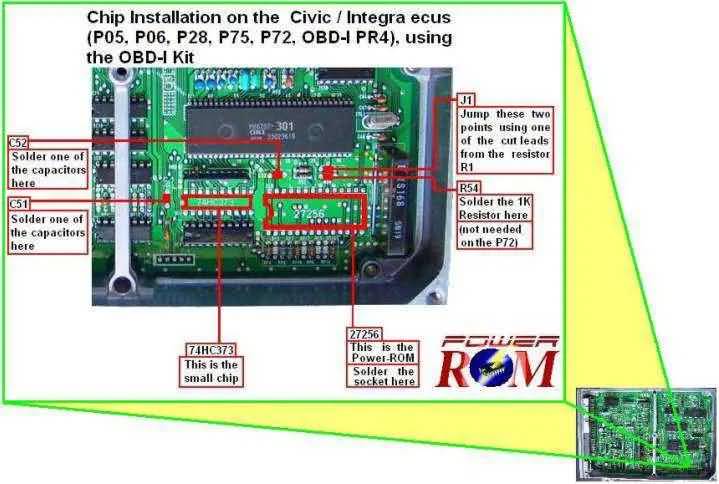

Start by removing all the 10 bolts (5 on each side) that hold the ECM covers. For the rest of the process, please refer to the drawing below:

On the components side of the circuit board, look for the footprint marks in the circuit, where the parts to be installed belong to. You will find six footprints at the lower right corner of the ECM if you have it in the same position as in the picture above. The six footprints are; “27256”, “74HC373”, “R54”, “C51”, “C52” and “J1”.

If your ECM hasn’t been “chipped” before, you will find the connections on those footprints covered with solder, but no components installed on them. Otherwise, there could already be some of the components in place. In that case, if a socket is installed for inserting the chip, your job will only be pulling the chip installed (if any) and inserting the new chip.

On the other hand, if the ECM has a factory-installed chip, normally done by Honda in some ECMS as a modification for converting from one ECM type to another, then the chip to be replaced will have a copper-colored label on it and will NOT be mounted on a socket.

In the two cases described above, the “OBD-I Kit” will not be needed, except for the socket in the factory chip case. About the factory chip case, it would be the most difficult case, because as mentioned earlier, the factory chip will be soldered with no socket and will have to be removed (desoldered) to be replaced by the 28-pin socket of the kit. Removing a directly soldered chip is not the easiest job in these models because of the already mentioned sensitivity to heat. If any moment after inspecting the job to be done you don’t feel like doing it, I suggest bringing the whole thing to a professional to do it for you.

If you think you can do it your self and decide to do so, one trick for desoldering the chip that can help is to first re-solder all the pins of the chip with excess solder to “rejuvenate” the connections. This will make it easier for the solder to flow when you are pulling it out with the soldering iron and a desoldering vacuum tool.

Desoldering braid will not be very effective for removing the chip. It is used for cleaning out the board by removing soldering from the connections when the parts are already removed and have them opened for inserting the new parts.

This job takes great care and patience, so please take your time to do it right, because although many accidents can be repaired, if an internal connection of the board happens to get broken somehow, may it be because of too much heating or because of too much force pulling the chip, it might be as bad as needing to replace the ECM.

For clearing the connections from solder for inserting the components, spread some solder flux over such connections on the circuit and proceed to remove the soldering by using the soldering iron and either the desoldering vacuum tool or the desoldering braid.

The connections on the board should remain opened and you should be able to look through the holes after the solder is correctly removed. After this is done on all the footprints of all the marked components, clean the circuit of excess soldering flux with the alcohol pads.

Installing the parts

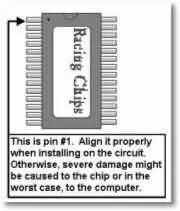

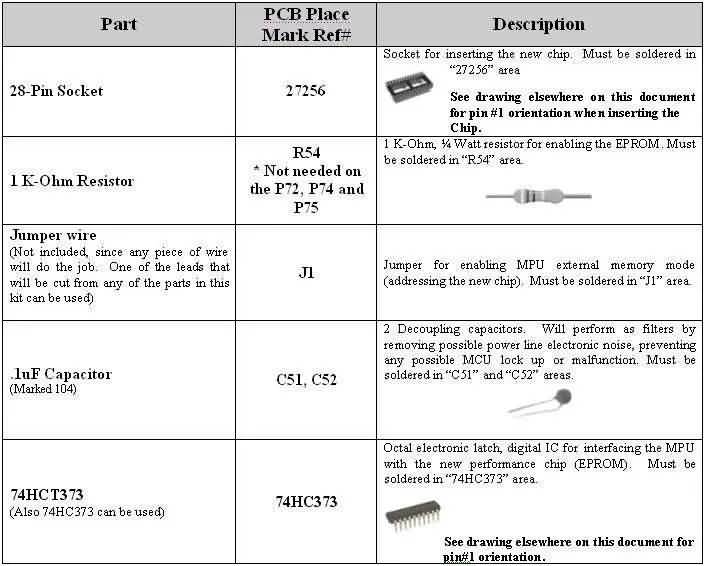

After cleaning all the pin connections area with alcohol, install on each footprint the corresponding part by soldering it to the circuit. Remember to install the 28-Pin socket instead of directly soldering the power-ROM in the “27256” footprint and make sure you put the pin#1 marking of the socket in the correct orientation to use it as a reference when inserting the chip. Care must be taken when soldering the “74HC373” chip not to (1) overheat it when soldering and (2) not to install it backward, so take note of pin#1 of the “74HC373” chip too.

After installing all six parts and inserting the Power-ROM in the socket, just put back the ECM all together and re-install it in your car.

The following table contains a list of the parts in the installation kit and their reference numbers on the circuit board, along with a brief explanation of their function in the circuit. Use it as a reference for easier location and installation.

NOTE: If the engine does not go over 3300-4000 RPMs after installing any chip, something went wrong, either with the installation or the chip was not good or not compatible with your ECM. You will find a troubleshooting guide in the link below should you have problems with your installation.

Troubleshooting Honda P28 Chip Installation

For those of you that might be wondering, “R54” is picked to be a 1k (1,000 Ohms) resistor, but values as high as 10K (10,000 Ohms) are being successfully used. This part is not critical as you can see, so if you can get a value from 1K to 10K, it will work, though the closer to 1K, the better.

One more thing, the jumper “J1”, as mentioned before, is to enable the reading of the external ROM you just installed (the chip). So, as you might be guessing so far, yes, it can be replaced with a switch to enable or disable the external ROM reading mode of the ecu, then enabling or disabling the extra power!

If doing so, please bear in mind that switch wires must be kept short to prevent electronic noise from being picked up like an antenna would do, and entering to the computer circuit, which might make it to behave erratically or to lock up on times. No more than 2-3 feet should be ok.

Also, many computers will require to turn off the engine and then on, for changes to take effect, while others will allow changes “on the fly”.

these ecus are easier than some others because there is no chip in place where you are goind to work. contrary to other that you have to remove the stock chip. good info.

That is right. Civic and Integra OBD-I ecus are easier to chip than their counter part OBD-I Accord and Prelude. On the first ones, you just remove soldering from the footprint and insert the parts. On the others, you must desolder the factory parts first, so the new parts can be inserted ans soldered. Nevertheless, for both jobs, skills on electronic circuit soldering and electronic parts management are required.

Thanks for reading,

Richard

Power-ROM chips are from:

http://www.OtherDeal.com

for the j1 what kind of wire are you reffereing to wire as in metal wire or wire as in a wire you run power through

Hello Jeff.

Either one. Just a jumper. It could be a piece of the leads of the resistor, a small piece or speaker wire or even a small paper clip. Something to make an electrical connection between the two points of “J1”. If it is a bare metal wire (no insulation), like a cut lead from a resistor, just make sure that it connects to the two points marked in “J1” and do not touch anything else.

Cheers,

Richard

Guys, as many have asked this, on the P72 (94-95 Integra GSR) and P74 / P75 (1994-1995 Integra LS) the resistor R54 is NOT needed.

Cheers

Rick

Hi!

With installing this chip,how large a performance I may count on an increase?

Hello. Performance from these chips vary from engine to engine, depending on #1 setup, #2 how good is the engine mechanically and #3 the weather and altitude where it is being used.

It will be anything form 2 BHP to about 10 BHP. The number might seem low, but the feeling will definitively tell the contrary and one single horse power may be the difference between winning or loosing a race or for less time in a quarter mile.

As usual, the recommendation is, the cooler the air entering the engine, the these chips will performs as cooler air is more dense than hot air, thus containing more oxygen concentration.

As an example for that, people who live in a hot weather Country, will experience small boost in power when driving at nights because of lower temperatures than at day time.

Cheers

Hi!

The engine d16z6, wm 4-1 complete exhaust system,5 kg of flywheel, cold air intake.

The engine went through a full renovation.

Largest performance until now 20celsius in a degree,

6400 turn s20-as with bill. (5–gears)(195/50×15).

A chip would be needed for this configuration!

Your proposal?

In Hungary the average temperature of my lodge, the climate (in summer 25-32c degree).

Thank you!

Hello Martin. For the D16Z6, the P28 is widely used, but since you are located in Hungary, I guess that your ecu is not an USDM model.

While all your mods are compatible with our chips, a chip for your car will depend on your ecu more than anything, so if you please let me know the complete number of your car’s ecu (“37820-P??-???”) I will be able to tell you for sure.

Cheers

Helló!

Ecu numbers:37820 P28 G01

Motor:D16Z6..

Thanks!

Hello Martin. Thanks for replying. Yes we sell the exact chip for that ecu that will go great with your mods, but right now they are in backorder.

There were an unexpected massive sale and we ran out of them. We are expecting them in a week or so. Anyway, the link is below, just in case you want to check once in a while for availability.

http://www.otherdeal.com/index.php?main_page=product_info&cPath=6_10&products_id=140

Very interesting information.

Thanks for this info. i just bought a chip from ebay and it didn’t include instructions. anyway i installed the chip and it fills little or no difference. it was pretty cheap anyway, so i guess i got what i paid for…

Hi

i have a P28 ecu and i want to convert to a P30 what chip i heve to buy?

thanks

You should buy then a P30 chip, but make sure that the conversion is made right, as must P30’s out there are JDM ecms, contrary to P28, which is USDM.

If you convert it right (I guess P28 to an USDM P30) then you will just need a chip for that USDM P30.

I hope this helps. For any other question you are welcome back.

Richard