Random Facts

THIS IS A VERY NICE EXPLANATION OF EVERY SENSOR USED ON CAR ENGINES

IMPORTANCE OF OIL CHANGE

How important is an oil change for your car’s engine? I will let Jason from the Youtube channel “Engineering Explained”, explain the basics about it.

HORSEPOWER Vs TORQUE

A horsepower equals 746 watts or the force that is needed to lift one pound up to 550 feet in one second.

As you can see, the factor “time” is included in its definition and precisely that, is what differentiates horsepower from torque.

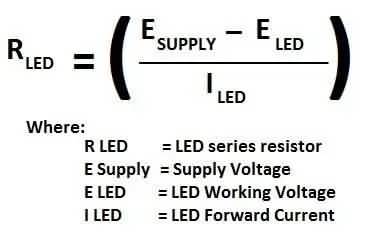

CALCULATING AN LED RESISTOR

Automotive LED applications mostly come already prepared and wired for directly connecting them to your car’s electrical system (12v). If this is not your case and you are looking for a specific resistor for powering an LED or LED product in your car, you can use the Ohms Law to calculate the value of the resistor. If you do not use a resistor in series with the LED and wire it directly to the 12-volt automotive electrical system you will burn the LED.

Simply subtract the working voltage (WV) of the LED, typically 1.8 to 2.8 volts, from the supply voltage of the car, which normally is 12.0v to 13.8v. Then, divide the result by the LED working current, which typically is 20mA or 0.02 Amperes. If you want to be exact, you will need the LED product’s electrical specifications, but it should tolerate some variation anyway.

LED Resistor Calculation Formula

You will find that using the typical values given here, the resistor will range from 460 to 600 ohms, but curiously, it is usual to find a 1000-Ohm (1K) resistor on pre-assembled units. That will cause the LED to be less bright than its capacity.

As an example, let’s say you have an LED with a forward current of 20mA (0.02 A) and a voltage of 1.8v (those are typical values for an LED), connected to a 12-volt circuit. In that case, it would be 12v – 1.8v = 10.2v. Then 10.2 / .02 = 510 ohms. That value, 510 ohms, is a commonly available value for resistors, but you can also use 470 ohms or 680 ohms which are the next lower and upper commercially available values.

MAF SENSOR CLEANING

To clean your MAF sensor, you can use “electrical parts cleaner” spray, the kind that leaves zero residues (non-lubricant).

You must uninstall the MAF unit and spray the chemical on its inner components. After that, it must be left to dry for several minutes, as moisture might condense because of the cooling effect of the spray.

A mild temperature blower is OK for the job, but not necessary.

Other than spraying it, remember to NEVER touch any of the internal elements.

COLD AIR INTAKE

The idea behind cold air intakes and RAM air kits is to provide the engine with the coolest air possible. This is desirable because the lower the temperature of the incoming air is, the denser it becomes, having relatively more oxygen content per volume.

The fact that incoming air ducts run near the engine, makes it absorb heat from the engine, partially leaning out the air from its oxygen content per volume by expanding it. Based on this principle, it will be a good idea to include some sort of insulation for cold air kits.

Maybe insulation might not be too aesthetic, but since those beautiful chrome runners are metallic, they tend to get too hot, going against the original idea of a “cold air” intake.

A good insulation for this is one that resists heat, like the insulation used in air conditioning systems, consisting of metal foil walls with some sort of fiber inside. The fiber will insulate the interior of the air duct from heat, while the metal foil coating will help to reflect the heat away from the outside of the air duct.

NO2 (NITROUS OXIDE)

NO2 Nitrogen gas, the main compound in NOS systems, is not a fuel and it will not even catch fire. Instead, it helps out combustion by providing a better oxidant than plain air. This oxidant is oxygen itself.

When NO2 gas decomposes at high temperatures, it liberates oxygen molecules and pure nitrogen molecules. The “N2” molecules (33% of the material) will escape to the atmosphere, while the O2 (66% of the material) will be used in the combustion chamber at the explosion stroke of the engine.

Problems with NO2 injected in the fuel mixture are; (1) it will produce much higher combustion temperatures and (2) it will need more fuel content in the mixture or a dangerous extremely lean air/fuel mixture condition may occur.

Example of a NOS / NO2 nitrous oxide kit for motorcycles

TURBONATOR

Vendors of the infamous “Turbonator” and such devices, make false claims about the product supposedly increasing performance by creating a tornado effect in the incoming air. They state that the created air movement, right after entering the intake manifold, in front of the throttle plate, will produce an increase in horsepower and other beneficial effects on combustion.

The truth is that several factors combined make the theory behind it to be incorrect, making the device useless. This was tested on the Dyno (a dynamometer) several times with negative results. It is possible that such a “tornado effect” is not even being produced.

Another factor is that the distance from the device to the throttle is too long. By the time the air reaches the throttle, there will be no “tornado”, if there was one anyway. In the end, the device will decrease the total diameter of the air path, making it just another restriction of the incoming air path that will result in nothing else than a power loss. The same goes for electrical fans put inside the air duct and the such.

You do not need to take our word for granted, of course, you may try it yourself. If you happen to have any real gain (with evidence), please submit a guest post on this website and we will publish it!

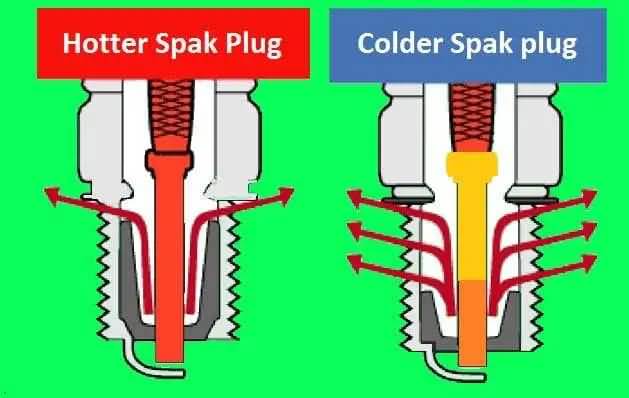

SPARK PLUGS

Using the recommended spark plugs is very important because of the working temperature or heat range they will produce. This heat range referred as to “hotter” or “cooler”, defines the ability of the plugs to dissipate heat from the center electrode (tip), produced by cylinder combustion. The less heat they dissipate, the more heat accumulated at the central electrode at a given time and the “hotter” the plug is said to be.

This temperature range can be “engineered” when the plug is being manufactured by primarily choosing the length of the ceramic insulation of the center electrode and selecting the metal type or alloy to be used, among other factors. So for “hotter” spark plugs, the longest the insulation, the less the exposure of the center electrode, the longer the heat will need to travel to be dissipated and the more the heat will accumulate. For “cooler” spark plugs it will be the opposite and the center electrode will be shorter with shorter insulation.

Spark plugs heat range is very important for the engine behavior at different speed ranges, as engines have different characteristics that make them need a hotter or cooler spark plug to avoid fouling at idle or avoiding power loss at high speeds. It will depend on design and requirements will be listed in the manufacturer’s specifications.

EGR (Exhaust Gas Recirculation)

It is true that the EGR valve helps a bit in lowering the overall engine working temperature, but it is nothing that the engine cooling system could not handle if the EGR was not present. The EGR’s main purposes are environmental. This valve is commonly closed at idle and at low engine speeds for not disturbing engine functions at such critical moments. When it starts opening at higher engine speeds, it recirculates a portion of the exhaust gas from the exhaust manifold to the intake manifold.

What the EGR does is re-injecting such an inert gas, depleted of oxygen, into the engine for re-burning. This lowers the combustion temperature because of the less total oxygen available. This will prevent toxic emissions of Nitrous Oxide gases (NOx or NxO), which only form in presence of Nitrogen (from the atmosphere, which is 78% Nitrogen), Oxygen (from the atmosphere too – 20%), high temperature, and high pressure (both from engine combustion stroke at high engine speeds). The EGR only kicks in after a certain amount of engine RPMs and the power loss caused by this system is so small that you won’t even notice, so don’t waste your time trying to eliminate the EGR, which will also fail the smog or emissions tests. It is not worth doing it.

JUMP STARTING

When jump-starting a dead-battery vehicle from another vehicle, it is Ok to start the engine of the vehicle supplying the charge after connecting the jumping wires, so the dead battery gets a faster charge via the alternator of the running engine before attempting to start the other car.

When trying to start the vehicle with the dead battery, it is ok to leave the jumping wires connected, to help the other vehicle to start, BUT, you must first turn off the engine of the vehicle that is supplying the charge to avoid any damage to the alternator. The alternator has an internal rectifier and regulator chip, which may get damaged if it is running when you attempt to start the engine of the vehicle receiving the charge.

Cranking current, which is the current that the starter draws from the battery when starting a car is very high (100’s of amperes). If the dead battery has still not got enough charge to supply such current, then the current it will be withdrawn from any other source available, which would be the good battery AND the alternator if running. The alternator rectifier and regulator internal chip can supply up to something near 50 amperes in regular cases (small cars). If it is forced to supply more than that, you may fry it.

So the best practice would be to connect the cables, leave the engine off, wait a few seconds while the good battery passes some charge to the bad battery and attempt to start the non-starting vehicle while the cables are connected. Once it starts, disconnect the jumper cables and start the other vehicle.

PCV VALVE

The PCV or Positive Crankcase Ventilation Valve purpose is to remove blow-by gases produced by piston movement, which accumulate past the piston rings inside the engine block, outside the cylinder or combustion chamber. These gases must be removed because they will eventually condense inside the engine block when not running and will be transformed into an acid, which will corrode the engine very quickly from the inside.

The PCV comes into the scene. It has a spring that forces it to open, but it will be closed at idle because the high vacuum pressure (negative pressure) of the engine at idle will be greater than the spring force. As soon as the throttle is opened, the vacuum escapes and positive pressure goes up, near atmospheric pressure (14.7 psi). Since there is not enough vacuum at that moment to surpass the spring force, the PCV will be then opened by the action of the spring and will allow the blow-by gasses to be sucked into the intake manifold to be burned by the engine. This was designed that way to allow to burn off the gasses only when accelerating and not disturbing the engine at idle. That is why the engine starts jumping and turns off by itself at idle when the PCV is damaged and opens at idle.

PCV Valve

HYDROGEN AS A FUEL (HHO)

The technology of using HHO or separating hydrogen and oxygen gases from water and injecting them together as fuel in cars, for one reason or the other, the technique is still not fully developed and though it is an excellent and promising idea, those “HHO” kits around the internet are unsurprisingly not performing as advertised. The worst thing is that people selling such kits know this but are still selling them using false claims.

Those vague “kits” are making more trouble than providing solutions. One example is internal damage of the intake manifold because of excess moisture generated by those kits, not to mention corrosion by sodium chloride vapors and other chemicals used as catalysts for the electrolysis of water. You should know that the amount of HHO needed for giving some results in car engines is a lot more than those kits can generate by far.

You should also know that when HHO burns, its main product is water. Though it is environmentally safer than carbon oxides, all that water will be inside your engine from the cylinders where the HHO mixture is burned, all the way to the exhaust manifold, catalyst converter, and the muffler.

The circuits, materials, and chemicals used on these kits haven’t been tested by any safety agency and could be a hazard for you and could possibly cause damage to your vehicle, including short circuits, fire, corrosion, engine malfunction, among others and of course, voiding any existing vehicle warranty.

HHO Generator Kit

Here is what they call a “Dry Cell” HHO Generator:

For this second one, we need to do some research on it. If you have any information or experience with it, please add a comment.

MAF AND AFM

The difference between the MAF (Mass Air Flow) sensor and the earlier AFM (Air Flow Meter) sensor, is that the AFM measures incoming airflow by volume, and the MAF measures incoming airflow by its mass.

That been said, the MAF is the most accurate of both devices when it comes to calculating how much air is really coming in, as mass may vary by temperature and other conditions, while volume may be steady under similar conditions. The MAF will be able to sense those variations and adjust measurements accordingly while the AFM will not.

Knowing exactly the mass of the air that goes inside the engine, may allow the ECM to do a more accurate calculation for the fuel needed to be injected.

Insulated Cold Air Intake for Toyota

Insulated Cold Air Intake for Toyota